Partners

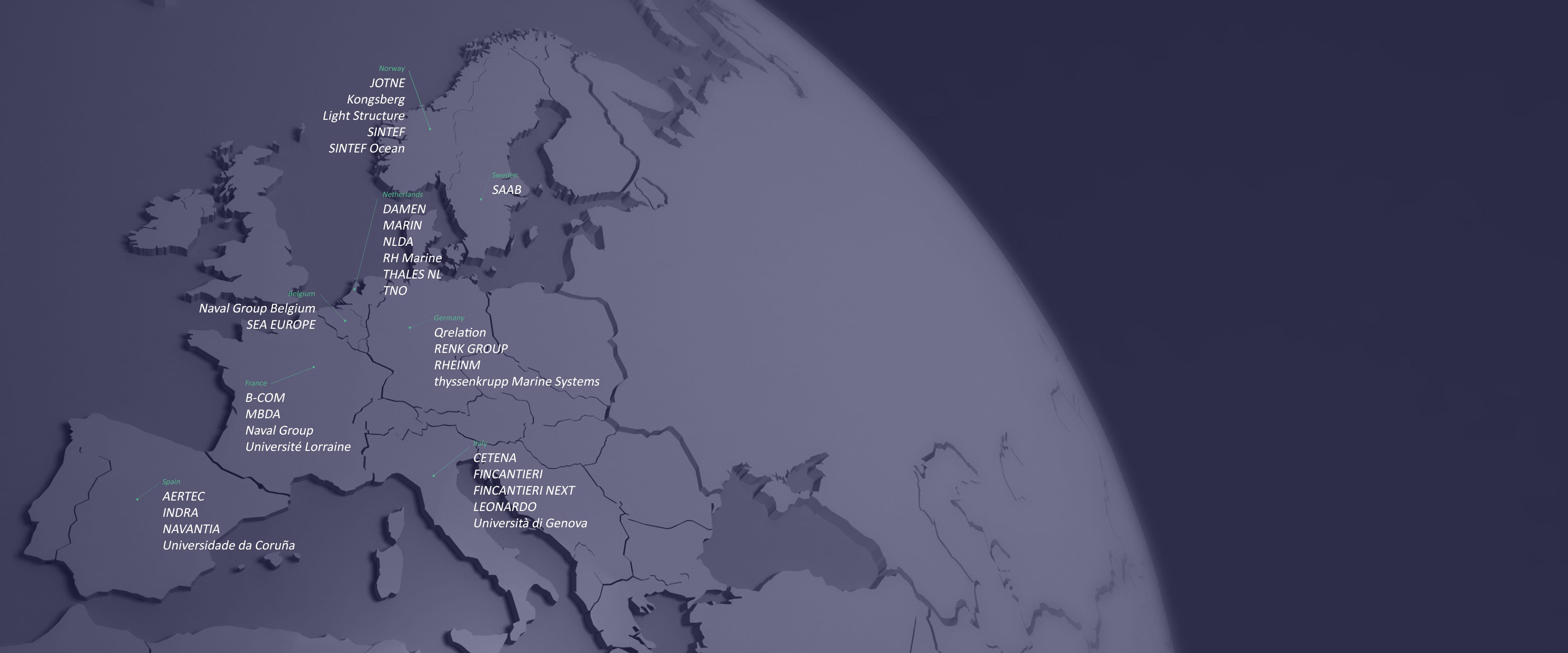

The EDINAF consortium is led by Navantia and is composed of 31 partners from 8 different countries (Spain, Belgium, France, Germany, Italy, Netherlands, Norway and Sweden).

AERTEC is an international company specialized in aerospace technology. It is active in the aerospace industry, defense and airports.

We have carried out projects and studies in 40 countries, we participate in the world’s largest aerospace programmes and we have reference projects at 160 international airports. Our value proposition is based on our in-depth knowledge of the aerospace and defense industries and airports and this specialization allows us to understand each domain with a complete vision, covering everything from operational processes and infrastructure design to onboard systems development and integration.

AERTEC will collaborate in three Work Packages 4-DIGITAL PLATFORM, 6-CONNECTIVITY and 8-DIGITAL TWINNING adding value to the development of a new Ship Digital Architecture based on its background concerning the model based systems engineering concept and the development of onboard communication systems with the aim of fostering the digital transformation in the naval environment.

b<>com is a private French innovation center that pioneers, designs and delivers technologies to companies that want to digitally boost their competitiveness. Its technologies are developed to address digital infrastructure, the cultural and creative industries, health, defense, and industry 4.0.Its experts come up with solutions in areas like 5G networks and beyond, image and audio processing, artificial intelligence, cybersecurity, cognitive science and mixed realities. Thanks to its world-class engineering team and its unique mix of scientific and industrial know-how, b<>com offers its clients technology innovations that make the difference.

b<>com is working on the WP10 and will bring its cloud expertise and consulting to the WP10. b<>com will participate in the selection of the cloud provider, provide expertise and global view of the proposed solution, and support the team in defining the test plan.

CETENA manages Research and Innovation, Engineering Consultancy, Experimental, Products and Training activities with its team of experts with professional competences, knowledge and experience.

CETENA also collaborates with different research centres in Italy and Europe and it is involved in many research projects with Universities, Ministries and industrial companies.

The dual principal aspects of CETENA are research and customer support which distinguish CETENA in the market through tangible advantages: on one hand the innovative support to the industrial sector provided by technicians involved in research activities, on the other hand a real contribution to research, thanks to the ability of CETENA of addressing research activities depending on the inputs received by the industry.

CETENA is already involved at the beginning of the project in the WP2 activities, where CETENA collaborates in the different substasks; CETENA is responsible for issuing the technical report related to TASK 2.5 for the Specification of DSSDA requirements.

CETENA provides technical contributions for the WP4, WP7 and WP9 to increase knowhow and experiences in the Digital Platform and MBSE, establishing a close collaboration among the EDINAF Partners

With roots stretching back almost 150 years – to the Royal Schelde yard in Vlissingen – Damen Naval is the only naval original equipment manufacturer (OEM) in the Netherlands. Having delivered more than 400 vessels to customers all around the world, we are a trusted partner in the international marketplace, known for our role as full-service provider, or integrator, throughout the lifecycle of our products. While taking pride in our heritage, we are looking towards the future.

Damen acts in the EDINAF project as lead nation partner for the Dutch partners in the project that all together represent the Dutch Naval Cluster. Apart from this Damen is Work package leader for the development of a decision support functionality that gives insight in the actual reliability and availability for one of the critical ship systems. Further contributions are supplied in the process of deriving end-user needs and requirements, datatypes, standards and exchange formats.

Fincantieri is one of the world’s leading shipbuilding groups, the only one active in all areas of high-technology shipbuilding. It is a leader in the construction and conversion of cruise ships, naval and offshore vessels in the oil & gas, wind, fishing vessel and specialized vessel segments, as well as in the production of mechatronic and electronic marine systems, naval furnishing solutions and the provision of after-sales services such as logistical support and assistance to fleets in service. The distinctive skills it has developed in managing complex projects mean the Group has an outstanding reputation in infrastructure and is a major operator in digital tech and cybersecurity, engineering services, critical infrastructure monitoring systems, advanced systems engineering for energy management in land-based applications and facility management.

Fincantieri leads the interacting with final stakeholders (MoDs, Navies and Industries) workpackage which will define the way ahead of the whole project.

Contribution to model base system engineering of the whole architecture and to the condition management use cases will bring the shipyard view on the designed infrastructure and its implementation effectiveness in the ship industry business.

The company has distinctive expertise in the fields of electronic systems, automation systems, ICT solutions, physical and logical security, digital engineering, integrated product support, digital twin and simulation solutions.

Fincantieri NexTech SpA are an end-to-end Product Leader and Integrator for Distributed system: Integrated Platform Management System, Electromagnetism and

Smart Materials Studies and Integrated Product & Logistic Support.

Focus on EDINAF Project: developed including the functional interaction with the IPMS (Integrated Platform Management System) on a digitalized base system where

the algorithms will be tested against reference historical data bases of ship performance and will form the reference calculation engine for PdM (Predictive Data

Management) module and the failure-management decision-making of MDSS (Maintenance Decision Support System).

The purpose and the new values defined for Indra are what identify the company. “At the Core” is the concept that is presented together with Indra, since it defines and reflects its strategic evolution: Indra is the technological partner of its customers’ key operations, it is at the heart of their businesses and it focuses on what really matters. The new values that identify and guide Indra are: Leadership - Generating real impact through tangible results; Flexibility - Enhancing proximity to the customer and differentiating Indra from its competitors; Focus - Projecting progress in a clear direction, which is crucial in the specialisation of business; Reliability - Building trust and long-term relationships based on experience and excellence.

Indra is a multinational technology company, which is a leader in the defence sector that intends to be involved in the definition of the fundamental concepts of the European digital ship of the future, contributing its experience in the definition of the digital platform (WP4), connectivity (WP6), integration of systems in the digital platform (WP7), definition of the digital twin (WP8), as well as developing a practical proposal for crew training applied to radar and EW management.

Jotne Connect is the leading provider of Product Data Solutions, based on open standards in the areas of Defense, Aeronautics, Space and Built Environment. Our suite of products has successfully reduced development and product lifecycle costs through the use of intelligent data management in a variety of industries.

Jotne Connect is a leader in the development of standards-based software products specializing:

- Product Data Exchange

- Product Lifecycle Management

- Long-term data & product OAIS archiving

- Data validation & verification, code checking

- Rules based data modeling

- Cross-platform data sharing

Jotne will focus on the aspects of - SPDM (Simulation Process and Data Management) and PLM (Product Lifecycle Management). The main contribution will be to the actions of establishing a collaborative framework for standardization in terms of data & models and to demonstrate continuous deployment of (software) systems in the digital twin integrated system environment and on board.

Kongsberg Defence & Aerospace (KDA) is a wholly owned subsidiary of Kongsberg Gruppen ASA and consists of eight business areas, each with a world-class product portfolio and a proven track record. Our divisions, and their 3,300 employees, strive to develop and offer innovative and reliable solutions for extreme conditions worldwide.

KDA is Norway’s premier supplier of defence and aerospace-related systems and solutions. Our portfolio comprises products and systems for command and control, information, data handling and surveillance, communications solutions, space technology, missiles and remotely controlled systems.

Within the defence and security area, KDA focuses on creating a safer and more secure environment for decision-making. Our customers demand exceptional reliability and precision, and KDA has the systems to meet these demands.

As Norway’s premier supplier of defence related systems and solutions, Kongsberg Defence & Aerospace (KDA) has the role of Norwegian National Lead in the EDINAF project. Furthermore, KDA is Work Package (WP) Leader for WP 11 – Operational Control System (OCS), which will build on and demonstrate many of the identified use cases in the project. Finally, KDA contributes in a total of nine other WP’s.

Leonardo is the leading Italian industrial company and one of the major Aerospace, Defence and Security players in the world. The Company has a solid industrial base in four domestic markets, a global commercial network, strategic partnerships and collaborations in the most important international programmes. Industrial skills and a long-term vision allow Leonardo to lead technological innovation over time. Digitalisation is the driver that accelerates the sustainable transformation of new technological cycles, enabling the integration between digital and manufacturing and supporting the green transition.

Leonardo will provide EDINAF Project with skills, experience and adavanced technological solutions with a focus on the emerging and disruptive technologies applied on both digital reference architectures and specific services to support the whole ship’s life cycle (e.g. Decision Support System, Digital Twinning and Digital platform). In particular, Leonardo will provide supporto to WP4, WP6, WP8, WP11, WP12.

Light Structures AS (LS) is a leading global supplier of structural monitoring solutions providing data enabling optimal operation and maintenance of assets in the maritime and infrastructure sectors.

Since its establishment in 2001, LS focuses on combining innovative fiber optic sensing technologies with state-of-the art software to provide insight to stakeholders in the Navy, Shipping and Offshore sectors. The head office and production facilities are located in Oslo, Norway.

Light Structures leads the task identifying and integrating the Ship Structural Health Monitoring (SSHM) use cases relevant for the Operation Control System (T11.6). This task forms the link to the EDF project dTHOR, dedicated to Naval SSHM.

We offer integrated solutions, from concept development and design to operation, making optimal use of our test facilities, computer simulations, simulators and full-scale measurements. In developing, applying and sharing our knowledge, we stimulate innovation and global collaboration. The knowledge and involvement of our people are our strength.

MARIN will use its expertise and extensive facilities to explore how data, condition monitoring, navigation systems and ship structural health monitoring can be used and optimized to achieve the objectives of EDINAF.

It is a leading global player in its field, capable of delivering the best and most advanced solutions to its customers, developing large joint European programs, offering its customers an unequalled range of products and services and uniting Europe’s major collaborative programs. MBDA has over 70 customers in the world with an annual turnover of 5 billion Euros. MBDA is shared by principal EU shareholders: BAE-Systems, Airbus Group and Leonardo.

MBDA has demonstrated its ability to bring together the best skills across the whole of Europe, and has succeeded in becoming the prime contractor for a series of strategic multi-national programmes. These include the six-nation (LOI) Meteor air superiority weapon, Cruise missiles Storm Shadow/SCALP and Taurus, a family of air defense systems based on the Aster missile (SAMP/T and PAAMS).

MBDA skills :

Since more than 20 years MBDA has developed a strong capability in the field of complex system design and manufacture, and associated netted command and control systems. For that reason MBDA has developed tools and methods to specify, down select, customize and integrate a wide range of assets, sub-systems, technologies, and advanced software’s solutions, such as the ones below.

MBDA will contribute to :

- The identification of the operational needs and their related system specifications

- The reference (Naval Cloud) architecture’s definition, from the perspective of the weapons engagements

- The Model Based System Engineering, from the Combat System perspective.

Naval Group is involved in the WP2 – Collecting, understanding needs and defining requirements, WP4 – Digital Platform, WP5 - Data, WP7 – Systems integration, and leads the WP3 – Digital ship reference architecture, WP9 – Building digital engineering + Digital thread using models and WP10 – Demonstrator.

Naval Group Belgium is a Naval Group subsidiary which focuses on Mine Counter Measure (MCM) and cybersecurity innovations. Naval Group Belgium works in both militaries and civilian projects and delivers best-in-class MCM and cybersecurity solutions. The CyberLab develops advanced cybersecurity solutions for cyberdefense in the maritime world.

Within the EDINAF project, Naval Group Belgium will bring its expertise in cybersecurity to assess and analyze the cybersecurity risks created by the digitalization of maritime systems. Naval Group Belgium will also develop a cybersecurity architecture to ensure that the digital ships are secured by design.

Navantia has a shiprepair line of activity that goes from regular repairs to refurnishment programmes, including conversions. The company has the facilities and know-how for complex repairs comprising LNG’S and Cruisers. Navantia has Fleet Maintenance Agreements with the most important ship-owners in the world. Additionally, Navantia has also taken steps towards diversification and has become a relevant actor in the area of offshores wind power, as a reference manufacturer of floating structures, jackets and electric substations. Navantia is also successfully delivering the conventional submarine most advanced in the world, S-80.

Navantia, as Coordinator, is the ultimate responsible for the successful progress and delivery of the project. We also lead specific workpackages, such as the project management, digital platform, connectivity, digital twinning, and crew training. Additionally. We are ensuring there is good communication among all the entities so the deliverables are consistent and aligned and also involving the Ministers of Defence so they provide insights throughout the duration of the project.

The Netherlands Defence Academy (NLDA) is part of the Dutch Ministry of Defence, and provides the (scientific) educational programs for future officers at the Navy, Army and Airforce. In addition, a range of scientific research programs is executed in technical, economic and strategic domains, both supporting the educational programs and offering knowledge and insights to the operational and support commands at the MoD.

The research in the technical domain is focusing on topics like Smart Maintenance and Life Cycle Management, Health and Condition Monitoring, Systems Integration, Alternative Fuels & Reduced Emissions, Unmanned Systems, Operational Analysis and Operational ICT. Research projects are always in close collaboration with the various stakeholders within the MoD, and with relevant industrial partners.

In the EDINAF project, the NLDA contribution is in the field of Predictive Maintenance. Methods and algorithms will be developed to automatically assess the availability and health status of on-board systems (WP13), making use of sensors and data that are available in digital ships. The information will also be used to develop and demonstrate a Predictive Maintenance application (WP14). Finally, the developed methods will be integrated in ship Digital Twins (WP8).

In aerospace, we offer comprehensive services in design, development, and process improvement. Similarly, in shipbuilding, our team excels in optimizing processes for superior vessel construction. Leveraging AI and ML technologies, we provide advanced digital transformation solutions that streamline operations and automate processes, unlocking valuable insights. With QRelation, you can achieve effective planning and realize your strategic objectives. As the driving force behind your visions, we combine engineering expertise, management capabilities, and digital transformation solutions to deliver tangible results. Partner with QRelation today and unlock the full potential of your projects.

QRelation is involved in two Work Packages of the EDINAF project, and our role consists of handling and connecting data in the whole digitalization process. We are dedicated to connect and unravel complex data structures in order to extract insights for smarter decision-making on naval ships.

We provide systems to ensure the reliable deployment of strong forces to set vehicles, vessels, and machinery in motion. Customers and users across world-wide defense, energy and industry sectors trust RENK’s engineered solutions for their performance and endurance in maximum-duty and minimum-tolerance missions.

RENK’s offering integrates design, engineering, production, testing and lifelong services of flexible, customized drive systems that translate power from any source of power into action. Headquartered in Augsburg, Germany, RENK Group operates 11 production sites in Germany, the U.S.A., Canada, Indian, Switzerland, the U.K., France, and a network of 20 technical and maintenance services locations around the world.

We will define the propulsion system and the considered operating modes based on the requirements needed. Additionally we will set up the propulsion system simulation model to analyse behavior in various modes of operation and combine these topics with state of the art condition monitoring options. Finalizing these tasks by validation with available data sets and development of optimized user-oriented HMI applications.

RH Marine is a leading and independent system integrator and innovator of electrical and automation systems in the maritime industry. We design and develop tailored and state-of-the-art solutions for complex Defence, Safety & Security ships & Yachts. At RH Marine, we focus on making these ships smarter and easier to operate.

With our innovative solutions and integrated systems, we reduce life cycle costs and decrease the impact on our environment. Together with yards, vessel operators, classification agencies and key-suppliers, we are a partner during the whole lifecycle of the vessel. We develop, assemble and integrate all hardware and software aspects of the installation. Our Rhodium solutions are the technological benchmark for our specialized industries. More information: https://rhmarine.com/en/

RH Marine’s role within EDINAF is twofold. RH Marine brings experience with private cloud solutions for operational technology (platform management system, navigation bridge system) onboard ships. Also, RH Marine supports the integration of stovepipe systems into an integrated mission management system.

Therefore, RH Marine participates in the following work packages:

- WP3 – Reference Architecture

- WP4 – Digital platform

- WP7 – Systems integration

- WP10 – Demonstrator

- WP11 – Operational Control System

- WP12 – Decision support for autonomous UxV’s and enhanced situation awareness.

Through our work in various fields, we at Rheinmetall take on responsibility in a dramatically changing world. With our technologies, products and systems, we create the indispensable basis for peace, freedom and sustainable development: security. Digitalisation, networking, cyber – the Electronic Solutions division covers the entire chain of effects in the system network: from sensors and the networking of platforms and soldiers to the automated connection of effectors. However, in accordance with the human in the loop principle, the decision on the effect is ultimately still made by the human being. This is complemented by solutions for protection in cyberspace. Other fields of activity of this Rheinmetall division include comprehensive training and simulation solutions, to which the company contributes over 40 years of experience.

Rheinmetall Electronics, located in Bremen, participates in the workpackages WP3, WP9, WP10, WP13 and WP15. Rheinmetall offers a broad range of training solutions for military and civil users in the domains of Armed Forces, public security, as well as industries and educational institutions in the transportation, merchant marine and energy and resources sectors. For the EDINAF project, Rheinmetall contributes high fidelity simulation models for chilled waters systems and electrical plant networks.

With over 80 years of industry experience, Saab has renowned expertise in delivering platforms, combat systems and sub-systems for the entire naval domain. All naval products and services in the Saab family have an origin in the context of a contested sea. A highly demanding setting with a high clutter environment and a military geography that generates large variations and highly compressed tactical situations, which constantly challenges you. From the littorals, Saab has reached the blue oceans with customer navies from different continents and is a trusted partner enrolled for the long run. Whether fully integrated or as stand-alone solutions, they are all expertly created and fully supported to deliver optimal operational effect. Here’s our complete offer within the naval domain: https://www.saab.com/products/naval.

Saab embraces the possibilities of working with external partners to find and develop innovative solutions that will take our society and industry further. Our role in EDINAF is to support and strengthen the positive impact on sustainable development through collaboration and sharing knowledge with our consortium partners to strengthen the European Defense. With customers in more than 100 countries and employees in 35 different countries and collaboration, our ability for research coordination and networking across all business areas provide a unique opportunity for pushing the boundaries of new technology.

SEA Europe has expertise and experience in the naval and military domains, acquired through the work of SEA Naval, its permanent working groups which gathers major naval shipyards and national shipbuilding associations encompassing six EU countries (DE, ES, FR, IT, NL, SE). Grasping the importance of European collaborative projects, SEA Naval members have jointly participated into many projects of the European and for the European Defence Agency. In addition, this cooperation has led SEA Naval and its members to propose common R&D vision, ambitions and priorities towards increased cooperation in the defence and security sectors. In that way, SEA Naval works as a R&D platform and acts as the EDA Naval Systems CapTech Industry Rapporteur.

As a partner of EDINAF, SEA Europe advises on best practices, helps to coordinate, and facilitates communication between project stakeholders. Additionally, SEA Europe is responsible for disseminating project outcomes to relevant stakeholders, ensuring that the project's impact is maximized. With its expertise and experience in project management, SEA Europe is a valuable partner for this project looking to achieve its goals efficiently and effectively.

Since 1950, our research has created solutions and innovation for society and for customers around the globe. This has made SINTEF a world-leading research institute. The SINTEF foundation is a non-profit research foundation. SINTEF Digital conducts research and innovation in digital technologies and technology-oriented social sciences. Our multi-disciplinary knowledge base is used across all industries and helps our customers exploit and meet the opportunities created by digitalization and digital transformation.

SINTEF Digital will provide Digital Twin technology with emphasis on predictive digital twins enabled by reduced order modelling and hybrid analysis and modelling. That is, we will enable real time predictions based on combining accelerated physics-based methods and data driven methods like machine learning.

Through cooperation in the SINTEF group, we are also able to integrate our own expertise with expert technological knowledge from other industry sectors. Our services include among other knowledge development, research projects, software development, testing and simulation, research reports and scientific publications, as well as seminars and expertise within a wide range of research topics such as aquaculture and fisheries technology, global ocean governance, coastal Infrastructure, marine environment, offshore wind and maritime transport.

SINTEF Ocean will mainly participate on defining the digital platform (WP4) with focus on interoperability, scalability, infrastructure and edge computing. In addition, we will be task leaders for Task 8.5 and Task 8.6 in WP8 (digital twinning). The digital twinning activities may also include use of the Open Simulation Platform (OSP) suitable for connecting different simulation models either run as on-premises or as cloud services.

In the markets of defence and security, aerospace and space, digital identity and security, and transport, Thales provides solutions, services and products to help its customers – companies, organisations and governments – to carry out their critical missions. Thales Netherlands B.V. (TNL) develops naval combat systems, sensors and SOTAS C4ISR solutions, that meet a wide range of needs for surface and anti-air warfare. These systems solutions perform surveillance, command, combat and communication functions and support other systems from both US and European manufacturers.

For Thales, R&D is collaborative by definition, and we work hand-in-hand with start-ups, industry partners and the academic research community to provide our customers with the most advanced solutions possible. Resolutely focused on the future, we are actively preparing the groundwork today for the disruptive technologies of tomorrow. Within EDINAF, TNL contributes to user needs & requirements (WP2), naval cloud connectivity & security (WP6), situation prediction for combat management systems (WP11), and UxV control/integration (WP12).

Around 3,100 people work at the Kiel site, making it the largest shipyard location in Germany. 185 years of history and the constant striving for improvement allow the company to set new standards time and time again.

thyssenkrupp Marine Systems offers its customers worldwide tailored solutions to meet the highly complex challenges of a changing world. The driving forces behind this innovative energy are the company’s employees, who shape the future of thyssenkrupp Marine Systems with passion and commitment every day. More information at: www.thyssenkrupp-marinesystems.com

Within the EDINAF consortium thyssenkrupp Marine Systems contributes its vast experience in the field of innovative system development. Responsible for the work packages “Data” as well as a partner in other relevant work packages, thyssenkrupp Marine Systems actively supports the development of a European standard for the Digital Ship and Ship Digital Architecture.

Within the unit Defence, Safety and Security, TNO uses its knowledge and technologies to create innovations for people who are safeguarding our peace and security on a daily basis. We support military, law enforcement, civil protection and other security professionals, in The Netherlands and abroad, with technological and behavioural innovations.

TNO contributes to the EDINAF operation control system with automated mission management functionality. The functionality is developed in support of coordinated collaborative operations of systems-of-systems, with specific attention for operator support and interaction. The automated mission management functionality will be applied to a boarding operations use case.

UDC has strong relationships with industry and businesses such as Navantia, Inditex, Repsol, Endesa…, some of which date back to the years of the very foundation of the University, in 1989. Namely, UDC maintains a close and fruitful collaboration with Navantia, whose results are visible in the Joint Research Center UDC Navantia (The Shipyard of the Future), a cooperation established in the year 2015 which, since then, is devoting all efforts in the digitization of the new block factory and the generation of new frigates through two main lines of research: Product Digital Twin, Plant and Process Digital Twin. More than 100 professionals from the academy and the shipyard are working hand-in-hand in this unique Research Center. Our participation as research institution in the project focuses on providing researchers with extensive experience in digital twinning, data management and IoT.

UDC participates in EDINAF contributing with the knowledge available in our leading research centers in Computing, Statistics and Naval Engineering, supported on researchers with extensive experience in applications in this Industry. We are pleased and honoured to participate in EDINAF as a unique international collaboration in the naval sector.

Within Universita’ degli Studi di Genova (Unige) is integrated the Electrical, Electronics and Telecommunication Engineering and Naval Architecture Department (DITEN) where the Naval Architecture and Marine Engineering Division is embodied.

Founded in 2012, the Naval Architecture and Marine Engineering Division of DITEN has its roots in the “Regia Scuola Superiore Navale”, founded in Genoa back in 1870. At present, it gathers people and facilities, skills and competences to enforce the educational and research/innovation activities in the field of Naval Architecture and Marine Technology. In such perspective, beside the development of a strategic focus on several specialist topics (e.g. ship noise emissions, composite materials,…) great attention is also paid to the issue of innovative ship design methodologies and safety rules/ship design process interaction.

UniGe participates for the total amount of 86 person months in EDINAF project divided between WP2, WP3, WP7, WP8, WP9, WP14. The contribution in EDINAF in terms of expertise ranges from a strong tradition in naval ship design processes to consolidated capabilities in simulation and digital modeling of ships and their performance.

For several years, the laboratory ERPI has been working on fundamental contributions to the analysis and understanding of innovative processes. ERPI's research activity has historically focused on the dynamics of innovation in organizations designing and producing goods and/or services. While at the outset, ERPI decided to focus on the problem of evaluation in a mono-criteria and individual dimension (anthropocentric design and analysis of the needs of "lead users"), the team has evolved towards notions of co-creation, resulting in more fundamental investigations into multi-criteria theories and complex process modeling techniques. Over the past 5 years, this shift in research has been aimed at investigating the collective and participative dimensions of innovation, as well as its systemic nature. The digital transformation (industry 4.0, smart cities…) has appeared as a new theme since it induces many changes (and innovations) in products and services, in technologies and in organizations (from the small team to the network of companies).

For more than 10 years, the team of researchers involved in the EDINAF project has been developing research activities in Systems Thinking, Systems Engineering and Systems modelling in a MBSE approach, Systems Interoperability, Enterprise Architecture Framework… Since 2010, they have participated to more than 20 industrial and European projects, and since 2021, they have been participating in a research chair with Airbus called ACTE MBSE - Actionable Collaborative Trustworthy Executable Model-Based Systems Engineering. It aims to contribute to Airbus’ ambitious program for the digital transformation of its R&D, launched four years ago (DDMS: Digital Design Manufacturing & Services).

They also transfer their research works in Master programs, since a part of the researchers has developed and is involved in the Master in Complex Systems Engineering of Université de Lorraine and in the graduate school of engineers, ENSGSI.

University of Lorraine is involved in EDINAF project or the total amount of 53 person months, in WP 9 and WP 10 for developing a Digital Engineering framework and Digital Thread Using Models and their implementation.